Case Study: Motionics Wireless Dial Indicators in Wind Turbine Gearbox Maintenance

Year: 2020

Location: United States

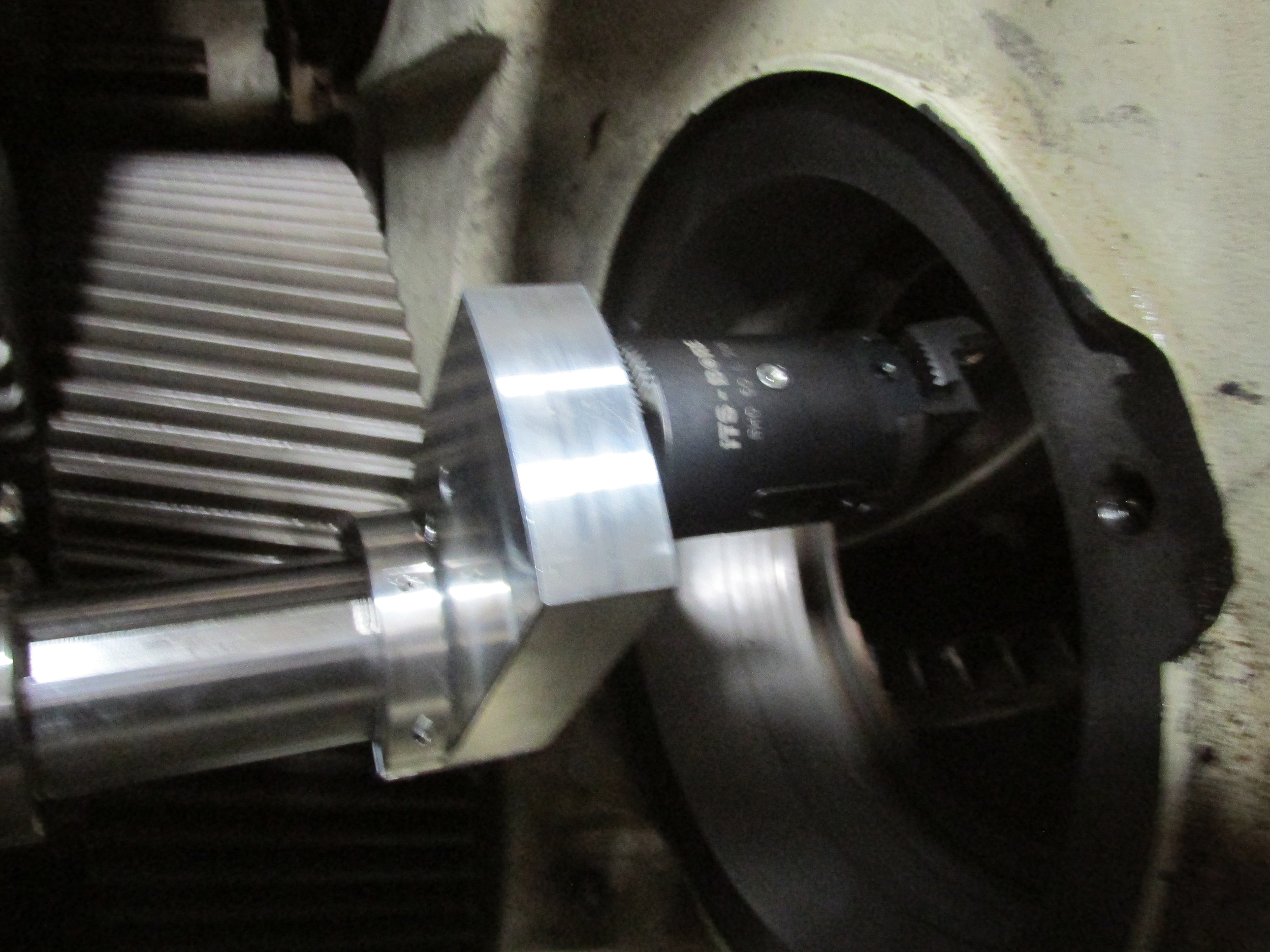

Hardware: BlueDial Wireless Dial Indicator – BD10-783

Software: MultiGage Reader

Application:

Certain models of wind turbine gearboxes will systematically develop a problem where the high-speed bearing outer race spins in the housing bore. This leads to egg-shaping of the hole, then to gear tooth misalignment, and ultimately, destruction of the gearing in the gearbox.

To prevent this condition from destroying the gearbox, the company in this case has developed a field repair that corrects the problem. This process involves boring the hole oversize, installing a sleeve, and then putting an anti-rotation device in the outer race of the bearing. This prevents the outer race from spinning.

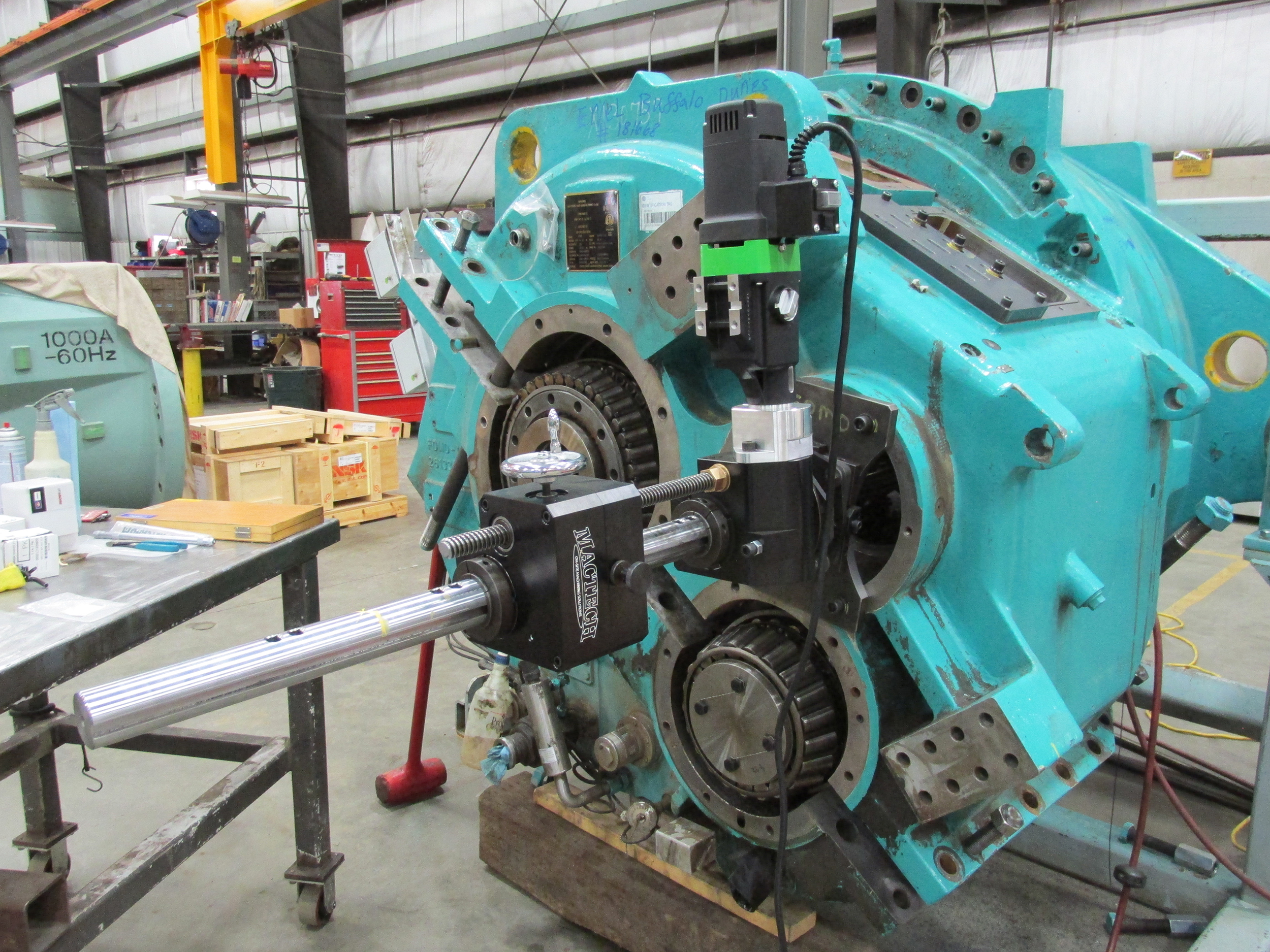

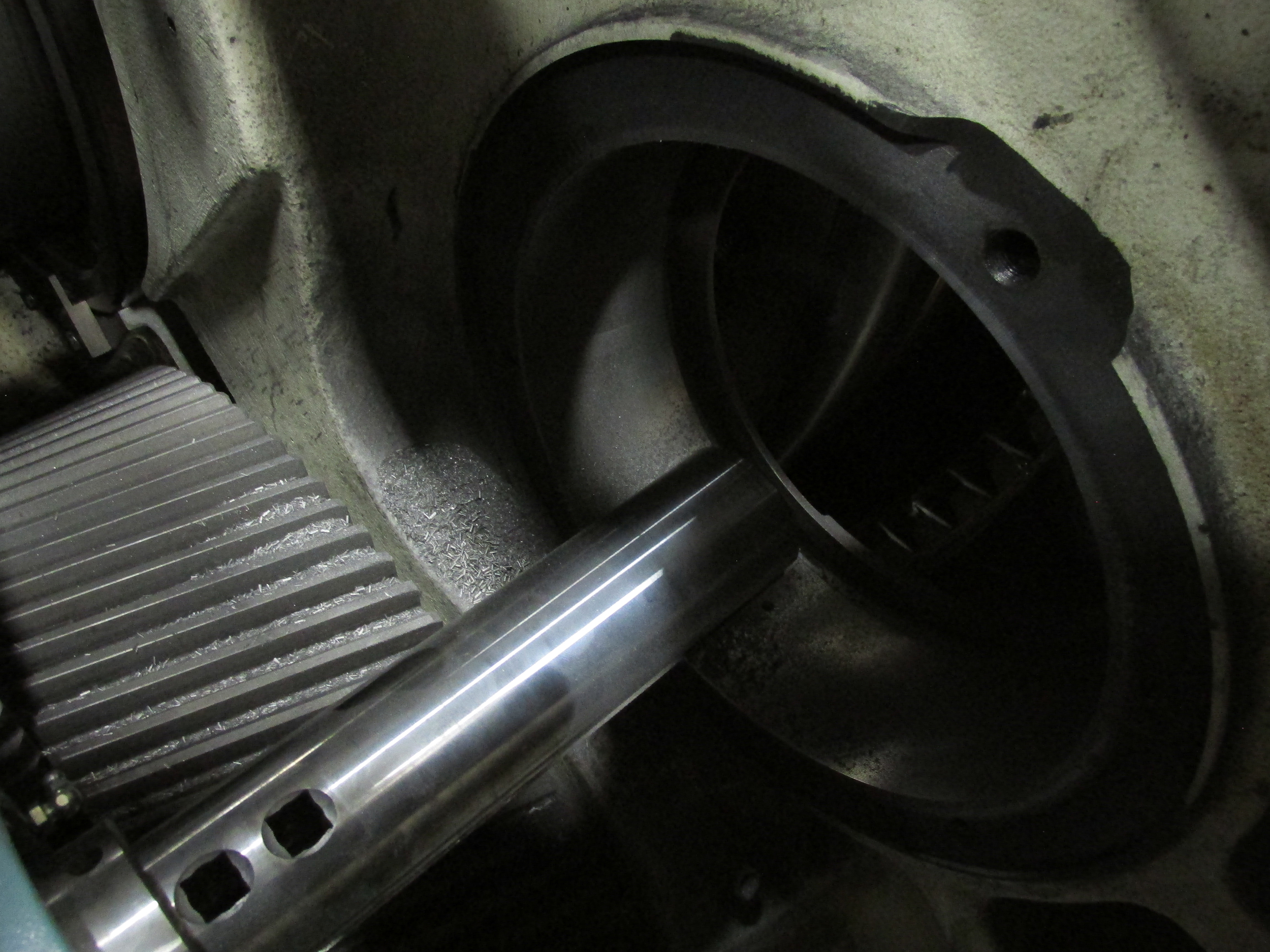

To conduct this repair, the gearbox must be mostly disassembled. Then, a boring bar is used to cut out the damaged material and then install a sleeve made from similar material to the gearbox case. This ensures that the thermal expansion range of the installed sleeve is close to the same as the housing.

BlueDial will transmit readings via Bluetooth to a smart device using Motionics’ MultiGage Reader application, so the user can view and record readings without having to look at the indicator face itself. The remote reading of the indicator allows the machinist to mount the indicator on the end of the boring bar and sweep the bore to set the alignment, and then again to verify that the final bore dimension is correct to fit the OD of the bearing.