Misalignment of Crankshaft in Marine Engines

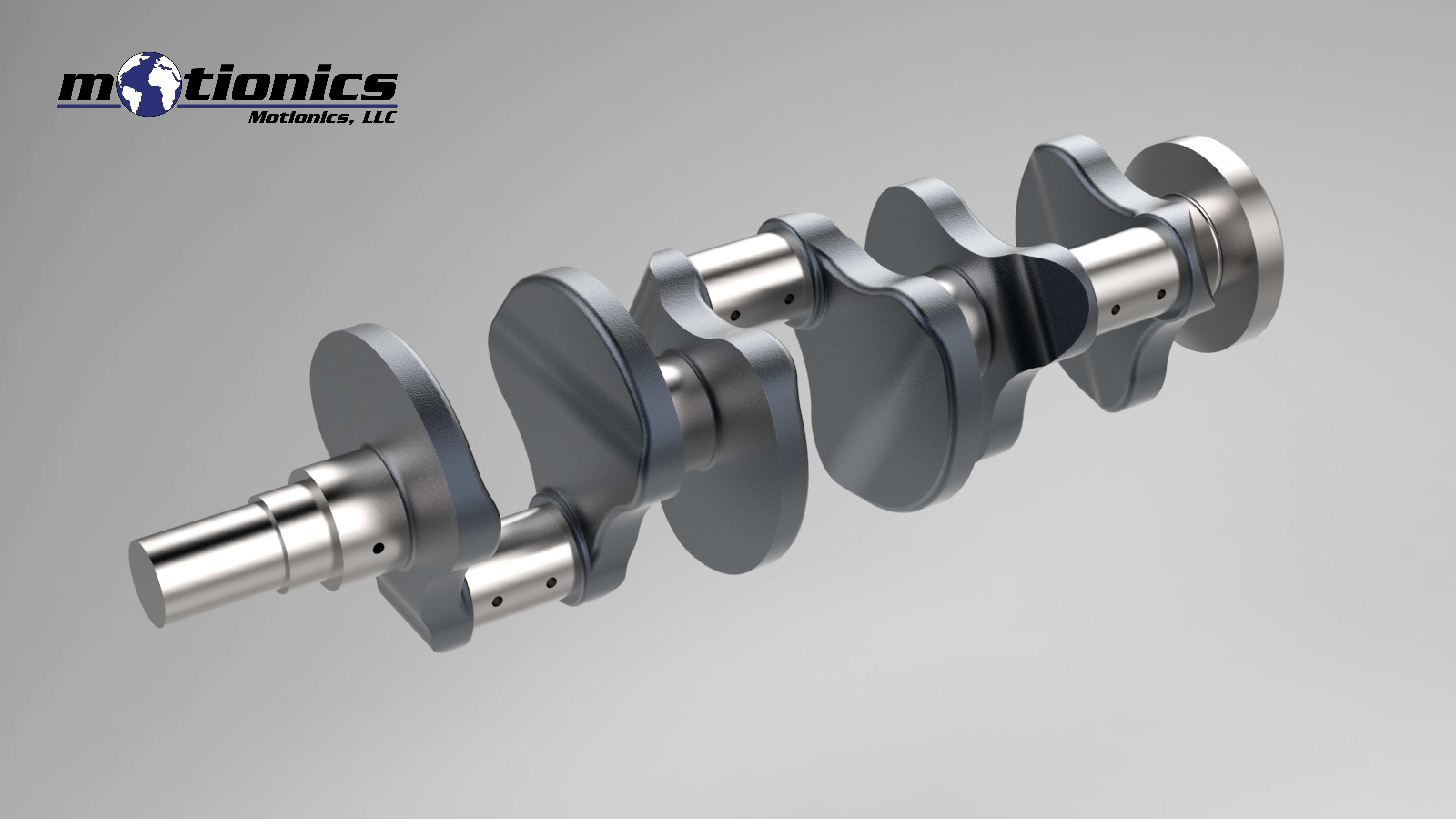

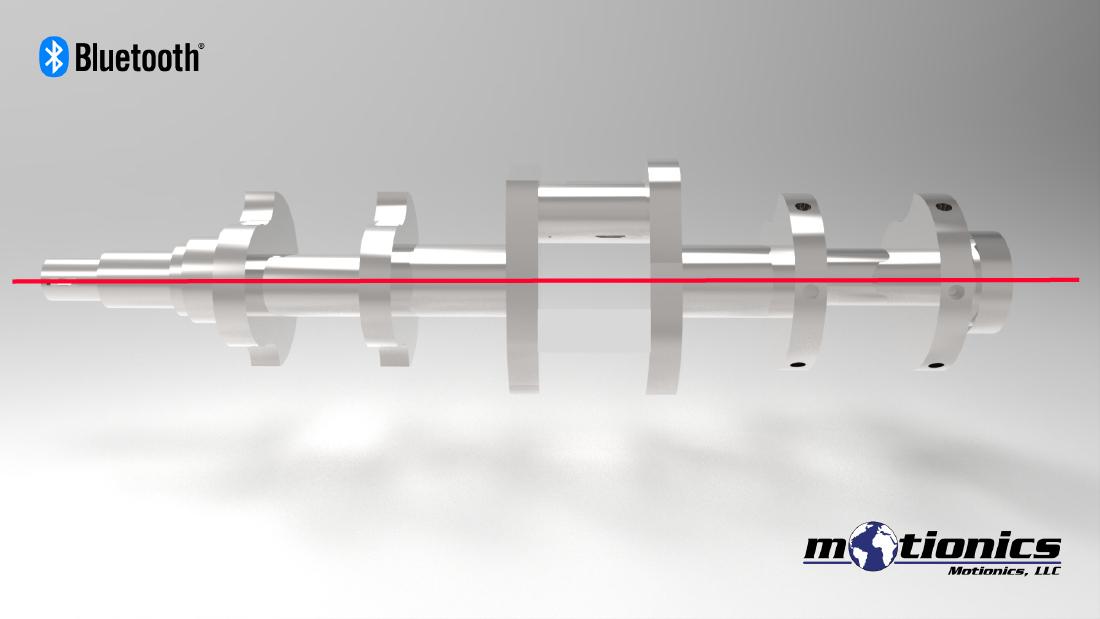

The crankshaft of a marine engine is a huge component when completely assembled in the engine. At first the entire crankshaft is adjusted in a straight line (association drawn from the center point of the crankshaft makes a straight line) before setting it on the highest point of the main bearings.

With time because of varying factors, the straight line may bend and become misaligned. A level of misalignment is bearable and acceptable to some extent; however, on the off-chance that the value goes past that rated by the manufacturer, it might prompt harm or even breakage of the crankshaft.

The following are the main reasons behind misalignment of a crankshaft:

- Wipe-out or damage of the main bearing

- Free engine foundation bolt leading towards vibration

- Deformation of ship’s body

- Crack in the bearing saddle

- Free main bearing bolt prompting damage of main bearing

- High bending moment on the crankshaft because of intemperate power from piston assembly

- Grounding of the ship

- Crankcase blast or fire

- A defective or destroyed stern tube or intermediate shaft bearings

- Free or broken chokes in the foundation

- Bearing pockets cracked

- Bed plate deformed – transverse girder damaged

- Tie bolts slack or broken

- Weakening of structure because of corrosion

Solana Blockchain Casino Integration Features Examined by Casinozoid

The integration of Solana blockchain technology into online casino operations represents a significant evolution in the gambling industry. As digital currencies continue to reshape financial transactions across sectors, the gaming world has embraced blockchain solutions to enhance security, transparency, and efficiency. Casinozoid’s comprehensive analysis reveals how Solana’s high-performance blockchain architecture offers unique advantages for online gambling platforms. With transaction speeds reaching up to 65,000 per second and minimal fees, Solana provides technical capabilities that traditional payment systems and even other cryptocurrencies struggle to match. This examination delves into how these features translate into tangible benefits for both operators and players in the rapidly evolving landscape of blockchain gambling.

Technical Foundations of Solana’s Casino Integration

Solana’s blockchain architecture employs a unique consensus mechanism called Proof of History (PoH), which timestamps transactions before they enter the consensus process. This innovation allows for remarkable transaction processing capabilities that make it particularly suitable for the fast-paced environment of online casinos. Unlike Bitcoin’s 7 transactions per second or Ethereum’s 15-30, Solana’s capacity for handling up to 65,000 transactions per second ensures that deposits, withdrawals, and in-game transactions occur almost instantaneously.

The technical implementation typically involves API integration between the casino platform and Solana’s blockchain. Casino operators can implement Solana wallets through either custodial solutions, where the platform manages private keys, or non-custodial approaches that give players complete control over their funds. The latter has gained popularity as players increasingly value self-custody of assets. premier Solana casinos have developed sophisticated systems that monitor transaction confirmations in real-time, allowing for immediate gameplay once deposits are verified on the blockchain.

Smart contracts on Solana enable automated execution of casino operations, including random number generation for games, payouts, and bonus distributions. These self-executing contracts eliminate the need for intermediaries, reducing operational costs while enhancing trust through transparent code that can be audited by third parties. The efficiency of Solana’s architecture also means that complex operations like provably fair gambling mechanisms can be implemented without compromising user experience.

Player Benefits and Experience Enhancements

The integration of Solana blockchain technology into casino platforms delivers several tangible benefits to players. Perhaps most notably, transaction speeds allow for near-instantaneous deposits and withdrawals—a significant improvement over traditional banking methods that may take days to process. This speed extends to in-game transactions as well, enabling seamless gameplay without interruptions for processing payments.

Privacy considerations also factor prominently in the appeal of Solana-based gambling. While transactions on the blockchain are transparent, they don’t necessarily reveal personal information about the participants. Players can maintain a degree of anonymity not possible with traditional payment methods that require extensive KYC (Know Your Customer) procedures. However, this varies by platform, as many regulated casinos still implement identity verification to comply with anti-money laundering regulations.

Cost efficiency represents another significant advantage for players. Traditional payment processors and credit card companies often charge substantial fees for gambling-related transactions, sometimes reaching 3-5% of the transaction value. In contrast, Solana’s transaction fees typically amount to fractions of a cent, allowing players to retain more of their funds for actual gameplay. This efficiency has enabled innovative casino models where house edges can be reduced, offering better odds to players while maintaining profitability for operators.

Operational Advantages for Casino Platforms

From an operational perspective, Solana integration offers casino platforms significant competitive advantages. The reduction in payment processing fees directly impacts profit margins, while the elimination of chargebacks—a common issue with credit card transactions—provides financial stability. Traditional payment processors often impose high fees on gambling businesses due to perceived risk, but blockchain transactions circumvent these intermediaries entirely.

Cross-border operations become substantially more streamlined through Solana integration. Conventional international payment systems involve multiple intermediaries, currency conversions, and regulatory hurdles. Solana’s borderless nature allows casinos to serve global audiences without the complexity of managing multiple payment processors for different regions. This global accessibility expands the potential player base while reducing administrative overhead.

Security enhancements represent another crucial operational benefit. Blockchain technology’s immutable ledger provides protection against fraudulent activities and disputes. Each transaction is permanently recorded and cannot be altered, creating an audit trail that protects both players and operators. Additionally, the decentralized nature of blockchain networks makes them resistant to single points of failure, reducing vulnerability to attacks that might target centralized payment systems.

Regulatory Considerations and Future Developments

The regulatory landscape for Solana-integrated casinos remains in flux as jurisdictions worldwide develop frameworks for blockchain gambling. Some regions have embraced cryptocurrency gambling with specific licensing requirements, while others maintain ambiguous positions or outright prohibitions. Casino operators must navigate these varying regulations, often implementing geo-blocking technologies and KYC procedures tailored to specific jurisdictional requirements.

Looking forward, several developments promise to further enhance Solana casino integration. Layer-2 scaling solutions may improve transaction throughput even further, while cross-chain compatibility initiatives could allow seamless movement between different blockchain ecosystems. Privacy-enhancing technologies compatible with regulatory requirements represent another frontier, potentially allowing compliant operations while preserving user privacy.

The integration of non-fungible tokens (NFTs) into casino ecosystems represents an emerging trend with significant potential. These unique digital assets can serve as collectible rewards, tournament entry tickets, or even representations of ownership in casino operations. Some innovative platforms have begun experimenting with decentralized autonomous organizations (DAOs) that allow token holders to participate in governance decisions regarding house edge settings, game selections, and profit distributions.

The evolution of Solana blockchain casino integration continues to accelerate as technological capabilities expand and regulatory frameworks mature. The combination of speed, cost-efficiency, and transparency positions Solana as a compelling infrastructure for the next generation of online gambling platforms.

In conclusion, Casinozoid’s examination of Solana blockchain casino integration reveals a technological framework that addresses many longstanding challenges in online gambling. The remarkable transaction speeds, cost efficiencies, and security enhancements offer benefits that extend to both players and operators. While regulatory considerations remain complex, the trajectory points toward increasing adoption as jurisdictions develop clearer frameworks for blockchain gambling. As the technology continues to mature, we can expect further innovations that enhance transparency, fairness, and user experience. The integration of Solana blockchain represents not merely a new payment method but a fundamental reimagining of how online casinos can operate in a digital-first financial ecosystem.

By taking regular inspections and precautionary measures, crankshaft misalignment can be managed and overcome to avoid any disaster.

Image credit: