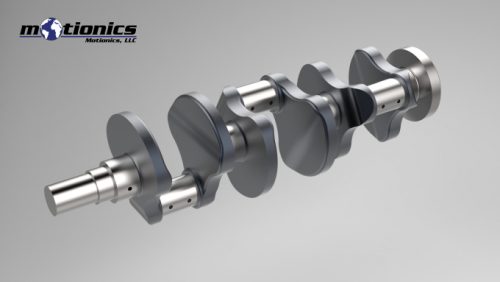

How Failure Normally Occurs in a Crankshaft

The crankshaft is the central part of the engine and it transfers the power of firing cylinder from the piston to a rotating propeller and, in case of a generator, it transfers the power of a piston to an alternator.

There are many reasons a crankshaft can fail, but the main reasons are listed below:

Fatigue Failure:

Fatigue failure is one of the major reasons for crankshaft failure in steel crankshafts. It may originate at the change of a cross-section, such as at the lip of the oil-hole bored in the crank-pin.

Failure due to Vibration:

Vibration in the engine while running specially torsional vibration is one main reason which can lead to a crack in the crank pin and journal to eventually crankshaft failure.

Insufficient Lubrication:

Insufficient and starved lubrication of the bearing in the crankshaft may lead to wipe out of the bearing and it eventually causes crankshaft failure.

Over pressurized cylinder:

If there is hydraulic lock (water leakage) inside the liner then, due to extreme pressure, then the crankshaft may slip or even bend.

Cracks:

Cracks are a big reason for the crankshaft failure and can develop at the fillet between the journal and the web, particularly between the position corresponding to 10 o’clock and 2 o’clock when the piston is at T.D.C.

The above mentioned are primary reasons for the failure of the crankshaft. Anyhow, time to time inspection and maintenance of the crankshaft can avoid big loss in form of crankshaft failure.

For more information please visit:

Reference:

https://www.quora.com/How-does-failure-usually-occur-in-crankshaft