Case Study: Wireless Deflection Measurement of Curtain Walling Systems in a Test Chamber

Year: 2020

Location: Bahrain

Hardware: Motionics’ Digital Dial Indicators with WiMER Transmitters

Software: MultiGage Reader

Application:

An ISO17025 testing facility based in Bahrain has developed methods for conducting tests that accommodate international testing standards for glazed curtain walling systems. With the help of Motionics’ wireless dimensional measurement tools, they were able to record deflection measurements for clients while maintaining the wind pressure conditions specific to each project.

A direct requirement of the testing standards for these systems is to provide the client with accurate deflection levels of the mullions supporting the glazing units under design wind loads. The chambers are designed to be airtight, with suction/pressure fans/blowers providing the pressure to simulate the effect of advised wind pressures for the project at hand.

In order to accurately record the deflection or movement of the glazing system, the operators needed to acquire inducers/deflection gauges and a monitoring system that could record deflection readings at given points of the system over the course of the test, all while maintaining the strict test conditions as required by each of the relevant testing standards.

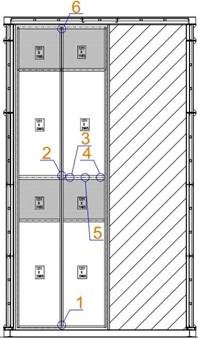

In a typical test, dial gauges are installed on the interior of the specimen as shown in Fig 1. The distance between the outermost gauges is measured and recorded, to be divided by the allowable deflection parameters to arrive at the permitted deflection. The internal test observer then enters the test chamber and closes the door.

They then apply and relax the load at varying pressures in both directions, taking deflection measurements with the dial indicator once each load is applied.

Without an alternative, recording the deflection gauge readings would require an operator within the chamber during the test to manually take photographs of the gauges at given points of time during the test. The company’s research into this issue highlighted the potential use of Motionics’ BlueDial wireless gauges, and our technical team was consulted to find a solution.

Digital dial indicators with wireless transmitters were the initial suggested solution. The dial indicators were found to fit the application’s accuracy requirements, but the wireless connection was not consistent within the purpose-built, airtight, insulated testing chamber, causing the records during testing to be interrupted.

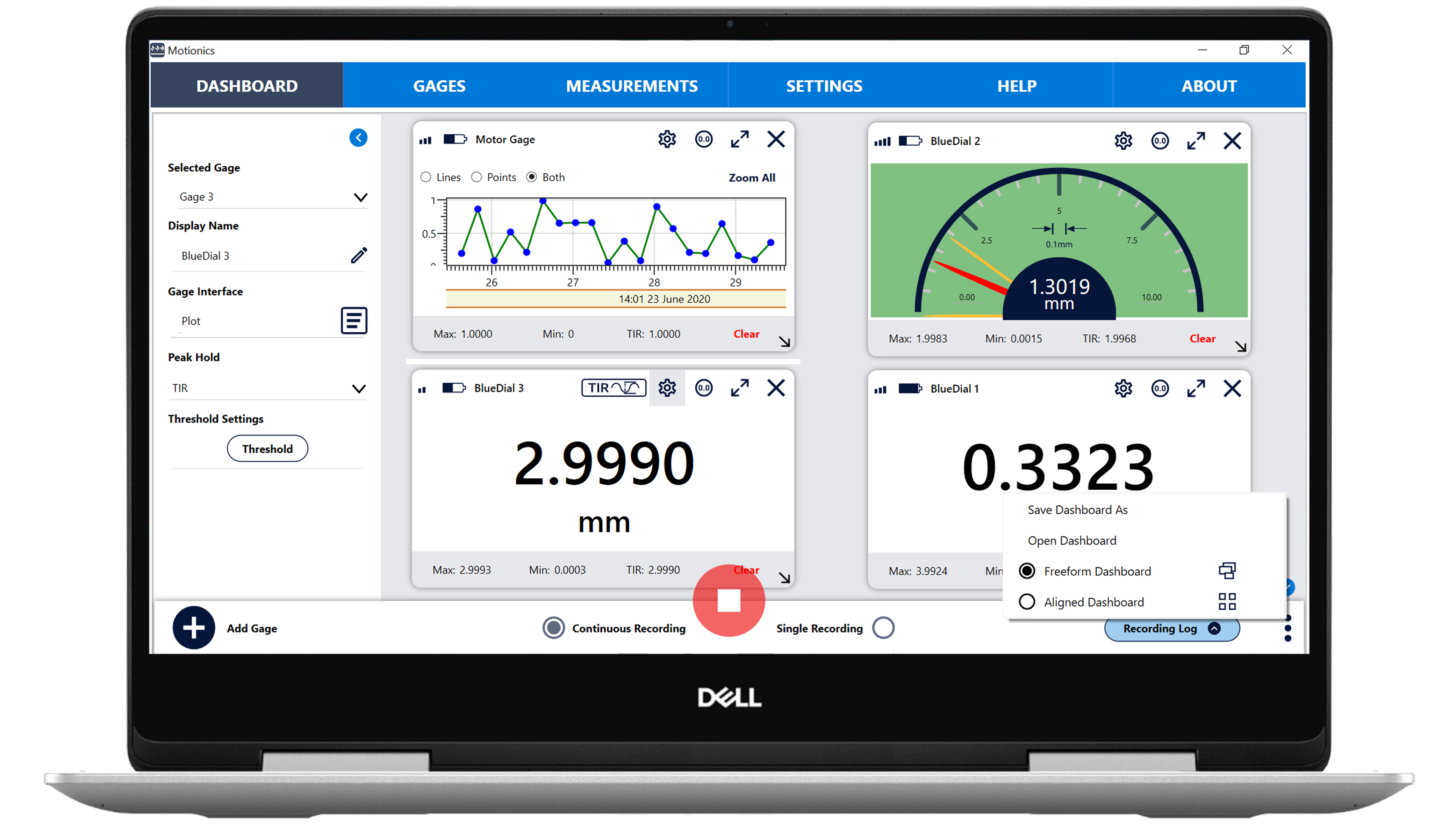

As an alternative solution, the digital dial indicators were connected to Motionics’ wireless measurement read (WiMER) Bluetooth transmitters via extension cords, which were routed to the outside of the chamber. From here, the WiMER transmitters would transmit readings from each gauge to the laptop running Motionics’ MultiGage software outside the chamber in the metering room.

With this setup, an operator outside of the testing chamber could view and record readings from all the gages at once, plot the data in real time, view the maximum, minimum, and total indicator reading of the displacement data, set thresholds for acceptable displacement ranges, and, most vitally, save and export the data as a CSV.

The company currently has a total of 10 indicators in use. This consists of a combination of 50mm and 100mm-range indicators placed at a height of 12 meters in the test chamber, connected via extension cables to WiMER transmitters that allow them to monitor and record data from all gages simultaneously.